Confidential Global Semiconductor Manufacturer

Industrial

Design-Build

Hillsboro, OR

April 2016

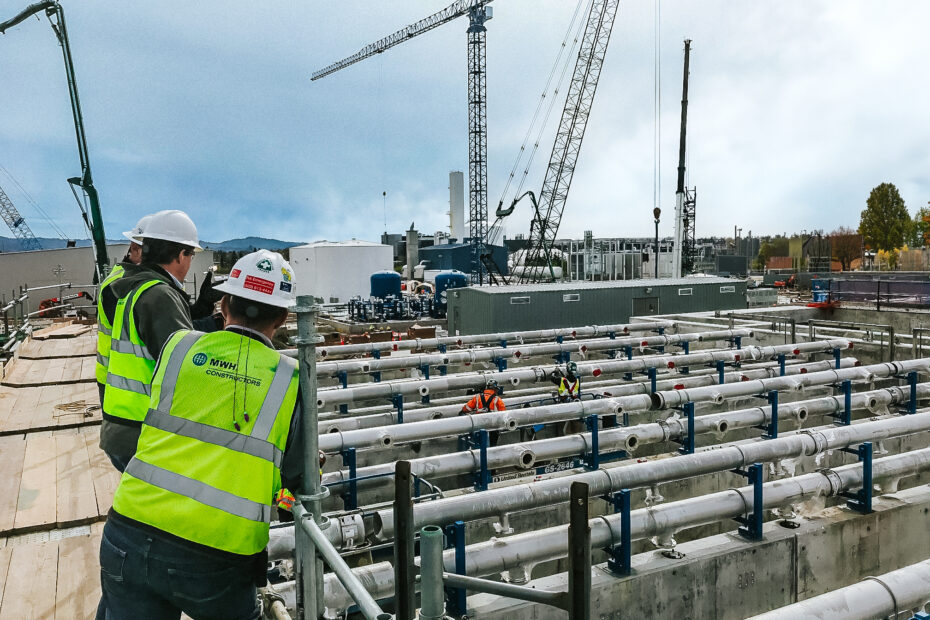

MWH was selected by a confidential global semiconductor manufacturer to develop, design, construct, and operate a facility to treat their fabrication facility wastewater for reuse and generate zero liquid discharge. The $417M plant uses Biological Nutrient Removal (BNR) / Membrane Bioreactor (MBR) combined with other advanced water treatment systems to reclaim a portion of the high-quality finished water effluent and make it available for use onsite in order to reduce the client’s need to purchase additional potable water for production needs.

The client uses the recycled water for cooling towers, chillers, and scrubbers. In addition to treating the overall wastewater stream to meet standards and reduce the need for discharge, the facilities also helped the client achieve sustainability goals by reducing overall water usage. The MWH team conducted a pilot project initially, using wastewater sampling, bench-testing, and process evaluations to gain an understanding of the key risks and challenges involved with treating the wastewater. Our in-house engineers and construction professionals collaborated through multiple value engineering and constructability workshops that resulted in overall project savings.

The facilities were sized for an initial capacity of 6.7 MGD and 8.35 MGD average and maximum flow rates, respectively, expandable to an end state capacity of 10.5 MGD and 12.39 MGD. Facilities include emergency and equalization basins, a pre-treatment chemical process, BNR/MBR, ion exchange, high pH reverse osmosis (HpRO), thermal brine concentration and crystallization, solids dewatering, chemical stabilization, and achieves zero liquid discharge. The facility’s primary structures include large, covered, concrete basins, steel and fiber-reinforced polymer (FRP) storage tanks, process equipment, and buildings for administration, maintenance, and chemical storage. Construction included demolition, earthwork, concrete, yard piping, process piping, all mechanical, instrumentation and controls, utility relocations, paving, and more.

After 200 years of making waves in water reuse technology, MWH constructed the first semiconductor water reuse facility in the US.